All rights reserved. Site Map

PET material is one of the few thermoplastics that can be recycled to achieve resin. Today post-consumer

bottle flakes are successfully used for food-contact packaging, high-IV strapping bands, and filaments.

Bottle-to-bottle recycling requires the highest standards in terms of decontamination.

Due to its favourable characteristics, the use of PET (polyethylene terephtalate) for food-contact packaging is a success story.

But it also causes more PET waste which in turn raises public interest in this issue.

Recycling contributes significantly towards a positive perception of PET packaging: It increases ecological awareness and induces collection of post-consumer waste and obligatory reuse of recycled PET (rPET).

Also major brand-owners jump on the bandwagon and promote low carbon footprint and resource conservation.

Crushing,Washing&Drying:

Applications(capacity: 300-2000 kg/h):

Suit for recycling Waste PET bottles, include Water bottles, Soft drinks bottles, Oil bottles, etc.

Specification:

The PET bottles recycling line is mainly composed of Shredder/Crusher, Helix Loader, Per-washer, Label Removing Machine, vertical Dewatering Machine, Dryer and other equipment.It is suitable for handling PET bottle. Material will be processed by label removing, crushing, washing, dewatering, and drying. The humidity of final output could be within 2%.The whole production line is easy to operate, efficient and low energy consumption.

Remarks:

1. LX PET recycling washing line includes all the effective washing machines, such as PET bottle pre-washer and hot washer, high speed friction washer, 3 sets of floating washer and 1 set of high speed dewater machine, all of these can assure you get best quality PET flakes.

2. PET bottle pre-washer is very useful machine in this recycling line, which will help you remove as much dirty, impurity, label as possible.

3. 5*40HQ containers are needed for the above machines, so if you tell me your destination port, I will let you know the CIF price.

Raw Material & Final Product

Project summary

| NO. | Item. | Spec. |

| 1 | Material | Waste PET bottle without label |

| 2 | Capacity | Capacity: 1000-1500 kg/h |

| 3 | Final products size | <16mm |

| 4 | Electricity power supply | 380V; 50HZ; 3Phase |

| 5 | Installed power | 330 KW (which is not including the steam boiler power consumption) |

| 6 | Power consumption/hour | 230kw/h (around 70% install power) |

| 7 | Water supply | The buyer should supply the water connection |

| The buyer should have the pools and water to supplying to the machine | ||

| The seller can by water treatment system supplier | ||

| 8 | Plant area | >600 Square meter |

| >5 meter height | ||

| Estimate line size 70m (Length)* 8m(Width)* 4m(Height). We can make the line turn as U or L shape to fit the plant | ||

| 9 | Water consumption | About 6T/hr, but can recycling use upon build the filtering tank or water treatment equipment. |

| 10 | Manpower | 3 Person required, 1 person feeding Bottle, 1 person packing and 1 person manages factory. |

| 11 | Others | Brand used in the Line: Contactor SIEMENS/ Schneider brand |

| Machine color indicated by the seller | ||

| 12 | Final flakes quality | |

| Technical Parameter | Specification | |

| Flakes size | <16mm | |

| Moisture Content | <1% | |

| PVC Content | <150ppm | |

| PH | 7.5+/- 0.5 | |

| Bulk density | 250-400 kg/m3 | |

| Intrinsic Viscosity | >0.70 | |

| Non-PET | <150ppm | |

| Color | <200ppm | |

| Suitable to be used for | Polyester / PET strapping/Polyester Fiber/ PSF | |

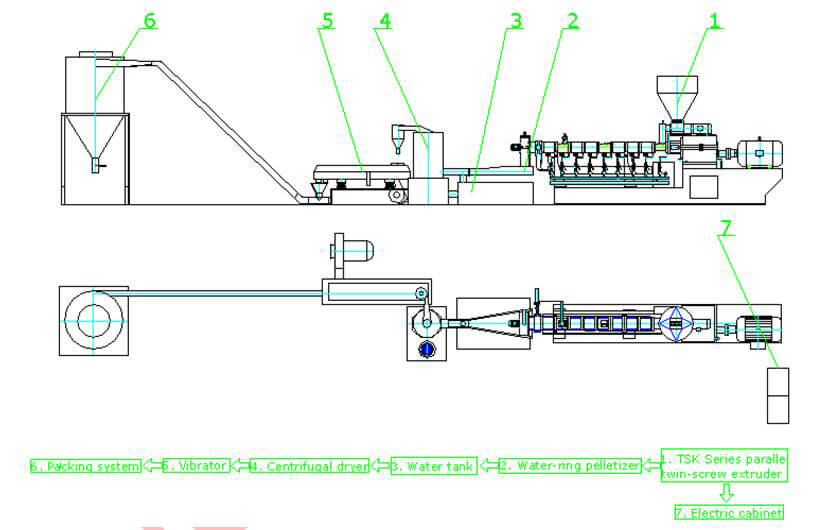

Pelletizing

We have agent in Australia, UK, USA and many other countries.

After you send us inquiry, our local agent will contact you ASAP.