All rights reserved. Site Map

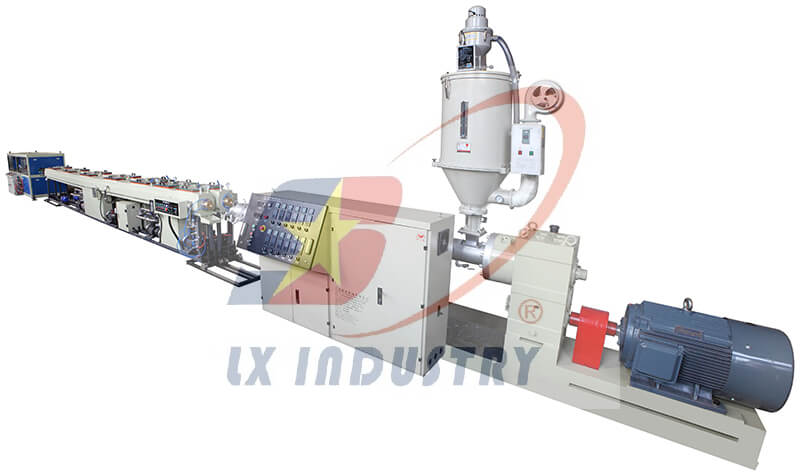

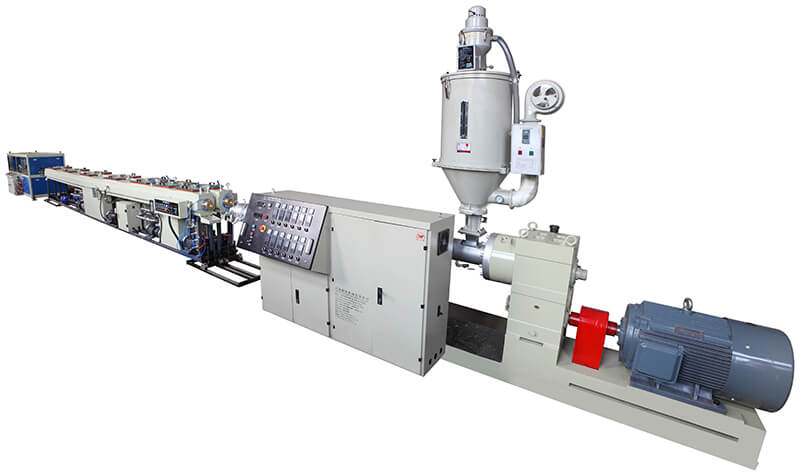

The production line uses one dead two out mould,a dead two out vacuum tank forming, vacuum calibration tank has full-stage vacuum cooling mode setting,Each pipe in a separate vacuum chamber stereotypes,hauling machine uses glue-block paws tractor,Traction speed can be controled, cutting machine uses blade cutter, stack has automatic unloading function, without manual operation.

The production line uses one dead two out mould,a dead two out vacuum tank forming, vacuum calibration tank has full-stage vacuum cooling mode setting,Each pipe in a separate vacuum chamber stereotypes,hauling machine uses glue-block paws tractor,Traction speed can be controled, cutting machine uses blade cutter, stack has automatic unloading function, without manual operation.

Feature:

Single-screw extruder:Using a long L / D, efficient screw extruder high-capacity, high plasticizing capacity.Extruder and hauling machine motor adopts imported AC / DC converter speed regulator.

2.Extrusion die: its spiral, good calibration, make good quality pipe production.

Internal heating system, high efficiency, easy to squeeze. Bronze calibrator for fast calibration and cooling ducts.

3.Vacuum calibration water tank and water spray cooling tank: using advanced water circulation and high pressure cooling system, vacuum degree adjusting device and automatic temperature and water level control system installation.

4.Hualing machine: crawler,it includes,two,three,four,six,eight,ten,twelve claw type,For different pipe sizes.

5.Chipless cutting, saw cutting or planetary cutting.Precision cutting, reliable performance, high efficiency. Meter device is also installed.

Pipe made through this line has produced excellent hardness and flexibility, heat resistance, aging resistance, high mechanical strength, environmental stress.

Cracking resistance and creep resistance, hot melt connection, and other advantages, which is the city's first choice for gas and water transmission tube.

Item | Extruder | Pipe diameter(mm) | Motor power(kw) | Capacity (kg/h) | L/D |

PEG-63 | SJ65 | 20-63 | 37 | 80-150 | 33:1 |

PEG-110 | SJ65 | 20-110 | 55 | 100-200 | 33:1 |

PEG-160 | SJ75 | 50-160 | 75 | 150-250 | 33:1 |