All rights reserved. Site Map

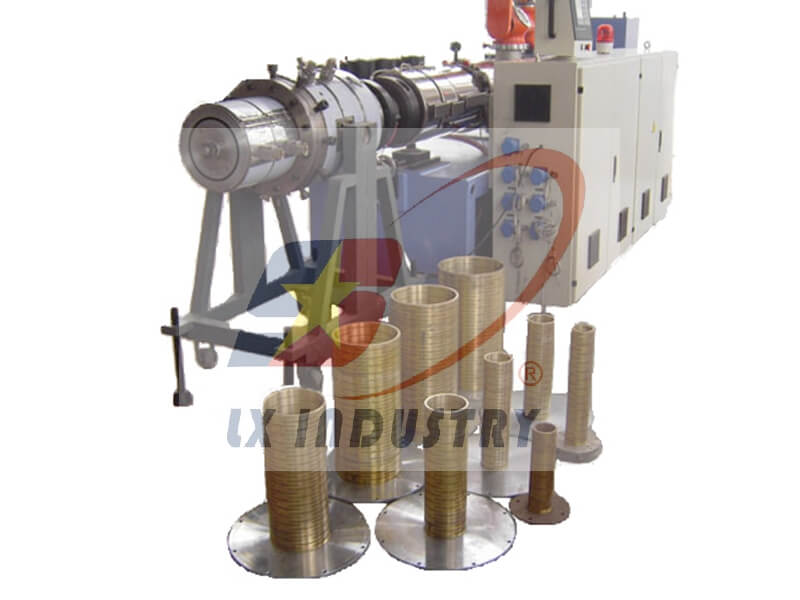

HDPE double wall corrugated pipe mould basic structure:

As commonly used pipe, double wall corrugated pipe is important tool to dredge and drain.As the forming mould when producing the double wall corrugated pipe, it has a little difference with the common pipe mould. The double wall corrugated pipe mould is consist of former model, later mold, insert items, row bit, slant, thimble, flow gate and so on.The shape and thickness of mould can infulence the final products.

When the wall thickness of the double wall corrugated pipe mold is too large, it will increase the cost of the production process, and will extend the product's molding time, resulting in decreased production efficiency. In addition, it is easy to make product quality too low, such as: bubble, shrinkage, dents and so on. When the wall thickness of the double wall corrugated pipe mold is too low for some complex shape products, manufacturing would be more complicated, and also easily lead to the finished product quality deviations. In pipe forming production, in as far as the special parts of the product is set to fillet, which can enhance the strength of the pipe so that it is not easy to deform or crack.

For the double-wall corrugated pipe molds used in the production, it is composed of a variety of common components thereof. In the manufacture of finished products molding process, the need of each member fitting tightly, so as not to cause the product burrs and so on.

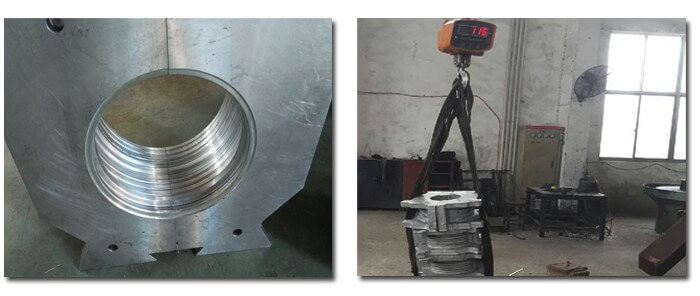

The company choose high quality aluminium alloy,Size Processed by CNC machining center , ensure size accuracy,In order to achieve beautiful product appearance.Due to the adoption of CNC machining,Each module is interchangeable.it can reduce Operator working intensity.

Mould features: Precise control of size tolerance and contraction rate,use advanced cooling system,Optimized Exhaust hole, Polishing treatment, advanced mold design.

In recent years, the market of plastic pipe is developing steadily in China. PE,PPR and UPVC pipe play an important role. Wherein the development of PE pipe is most remarkable.PE pipe has a wide range of application. Wherein the water supply and gas pipe is one of the largest application market.

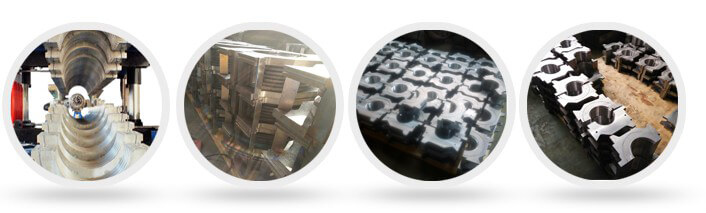

Our company receive good reputation because of the reliable quility and reasonable price. We have rich experience in producing PE pipe mould. The development of PE pipe market is also bound to a higher requirement of pipe mould. Our mould has high quality 3Cr17 Mould Materail and high service.

Features:

1.Using the overall flowing path core support structure.

2.Using the removable locating devices.

3.The channel design has avoided the dead area and retention.

4.The optimized design of the flowing channel gives it a stronger impact resistance .

5.The inside and outside surface of the profile is smooth and without scratches.

6.Easy to assemble and disassemble.

7.The mould has high stability and high extrusion speed.

Name | Plastic Extrusion Pipe Making Mold |

Size | Various types |

Mould material | 3Cr17, 3Cr17MoNiV,or as per your request |

Mould cavity | 1 or multi-cavity |

Mould composition | Die head, aluminum heating bands, calibrators and water tank |

Feature | Selectable co-extrusion of different raw materials: PVC, PP, PE, ABS |

Selectable technology: low-foaming, high-foaming & substance co-extrusion | |

Stable discharging, high efficiency, superior quality | |

Test | Mould will be tested to get the satisfied sample before delivery |

Service | Provide complete set of production process and technology transfer service |

Lead time | 35-40 days |

Package | Wooden case for exporting, each mould will be cleaned before packaging. |