All rights reserved. Site Map

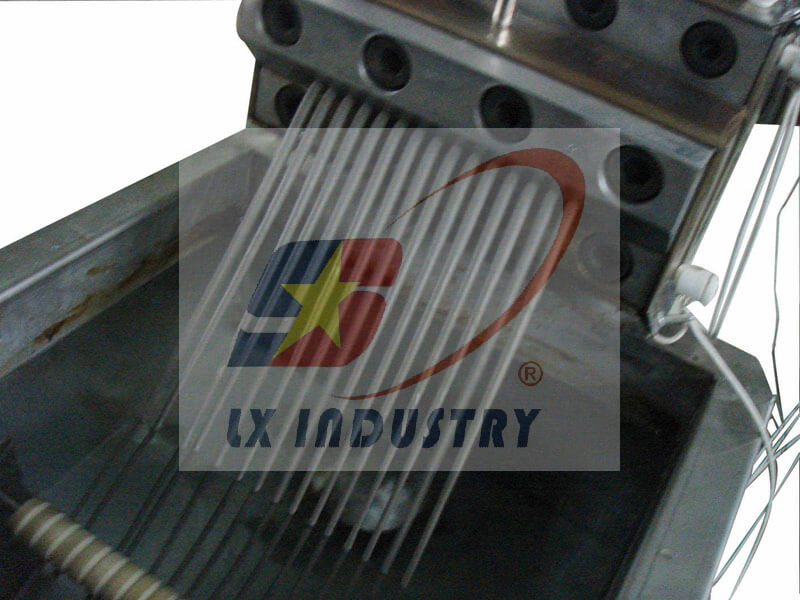

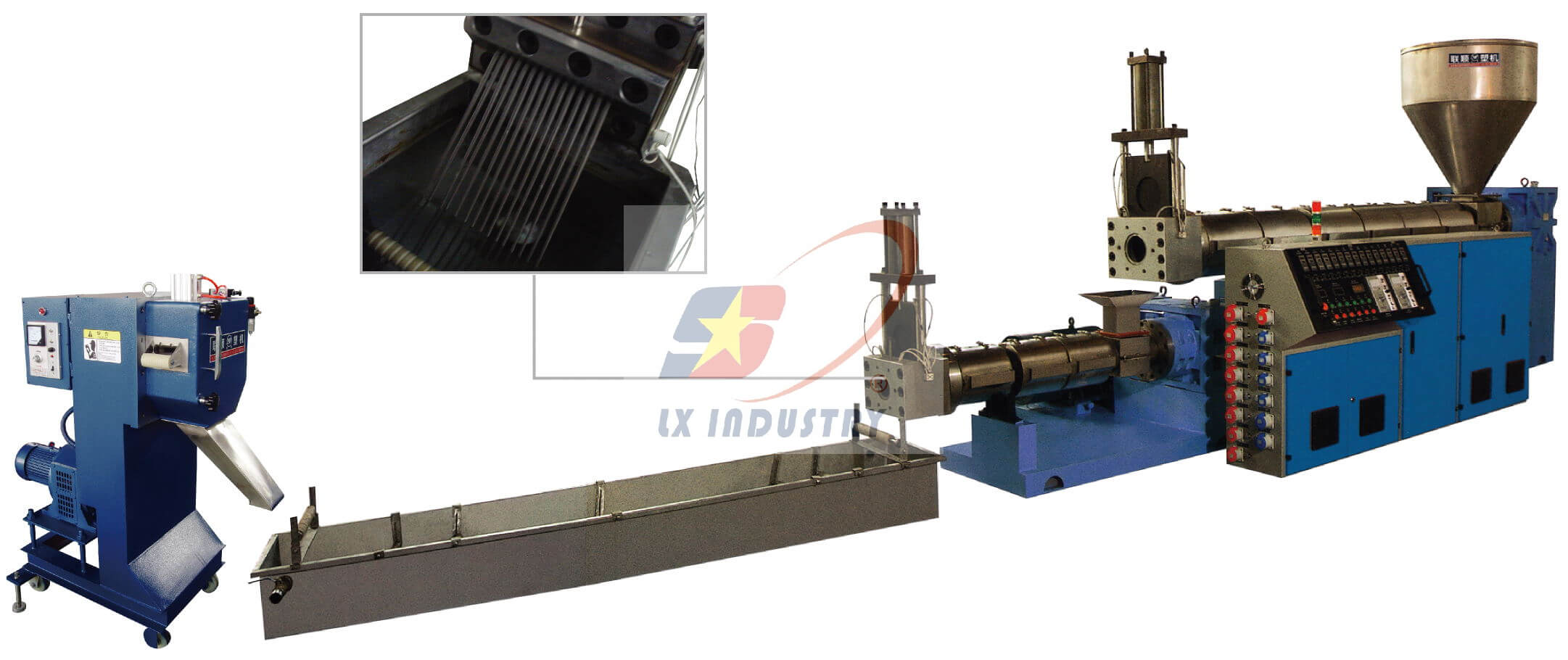

This machine consists of a single screw extruder, hydraulic network, granulation head, cooling water tank, granulator, fan cooling and storage box etc.The unique design of screw , suitable for all kinds of raw material granulating, dyeing and regeneration.The output is two times the general models.Special mould design can make granulate more uniform,The unique design of cutter and hardened resulting in longer equipment life. Water-cooled pull strap granulate production line is by extrusion granulation ,with parallel twin-screw extruder or single screw extrusion machine and corresponding granulation auxiliary consisting of granulating equipment.

This machine consists of a single screw extruder, hydraulic network, granulation head, cooling water tank, granulator, fan cooling and storage box etc.The unique design of screw , suitable for all kinds of raw material granulating, dyeing and regeneration.The output is two times the general models.Special mould design can make granulate more uniform,The unique design of cutter and hardened resulting in longer equipment life. Water-cooled pull strap granulate production line is by extrusion granulation ,with parallel twin-screw extruder or single screw extrusion machine and corresponding granulation auxiliary consisting of granulating equipment.

Product features:

1.The production line’s main gear box is high torque design,to realize a low noise and stable operation performance.Water-cooled pull strap granulate production line’s screw and barrel is by special surface treatment,With abrasion resistance, good mixing effect, high production characteristics.

2.The design of the vacuum exhaust and natural exhaust can remove waste water and waste air in the production process,all the materials are more stable, more dense particles, ensuring the product quality.

3.Hob type cutter has the characteristics of steady rotation, even granule cutting, variable frequency energy saving, safe operation etc., the special design of the mould make granulate more uniform,The unique design of cutter and hardened resulting in longer equipment life. According to different needst can be equipped with air collecting device and drying equipment.

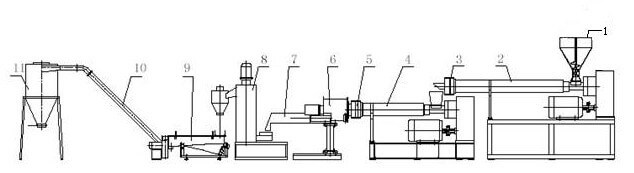

The process flow of PE PP film pelletizing line is as following:

Side-forcing feeding system→ Extruding system→ Die head and high speed net exchanging system→ Extruding system→ Die head and high speed net exchanging system →Water ring pelletizing machine → Dewatering machine→ Vibrating sieve→ Air blower→ Storage hopper

1 | Side-forcing feeding system |

2 | Extruding machine |

3 | High speed net exchanging device |

4 | Extruding machine |

5 | High speed net exchanging device |

6 | Water ring pelletizing device |

7 | Dewatering Machine |

8 | Vibrating sieve |

9 | Air blower |

10 | Storage Hopper |

11 | Control cabinet |

SJ series two stages pelletizing(with side feeder) | ||||

Model | SJ-100/100 | SJ-120/120 | SJ-150/150 | SJ-200/200 |

Screw Diameter | 100 | 120 | 150 | 200 |

L/D | 28-30 | 28-30 | 28-30 | 28-30 |

10~15 | 10~15 | 10~15 | 10~15 | |

Capacit | 120-180kg/h | 220-300kg/h | 300-400kg/h | 500-600kg/h |

ML series single stage pelletizing | |||||

Model | ML-85 | ML-100 | ML-130 | ML-160 | ML-180 |

Screw Diameter | 85 | 100 | 130 | 160 | 180 |

L/D | 25-42 | 25-42 | 25-33 | 25-33 | 25-33 |

Capacity | 120-180 | 250-350 | 400-500 | 550-700 | 800-1000 |